Nidek Me 1200 is the highest-end model of NIDEK lens edger, has earned an exceptional reputation for being the solution to meet a wide variety of lens finishing needs. In fact, the Me 1200 exceeds today’s demands with high-performance features including the world’s first automatic 3-D drilling and design mode.

The multifunction edger Nidek is designed to make all your jobs. You can grind, mill, cut, drill, groove or inlay glasses.

Nidek Me 1200 Lens Edger cutting system allows you to create exclusive forms for your consumers. Use its special high-curve lenses edger and its cutting function for the most shapely sunglasses.

Nidek Me 1200 Lens Edger Machine is an innovative lensmeter that has a 3D glasses drilling system. The device has a compact size, a large screen and has high precision material processing technology.

In addition, the Nidek vertices meter operates at a low noise level without vibrations. The Nidek ME 1200 lens is a multifunctional machine compared to the Nidek LE-1200 non-pattern edge sander. It also includes a blocker, plotter and centering ICE 1000 that performs drilling, grooves, and matacantos, modification of the frame.

The machine is equipped with a warning system for the wear of the components to be able to replace them in a timely manner. Nidek Me 1200 Lens Edger eliminates the sharp edge of the lens, taking into account all the characteristics and forms. The device is equipped with the latest electronic system to calculate the time and mode of operation.

Features

- Automatic 3-D drilling and grooving

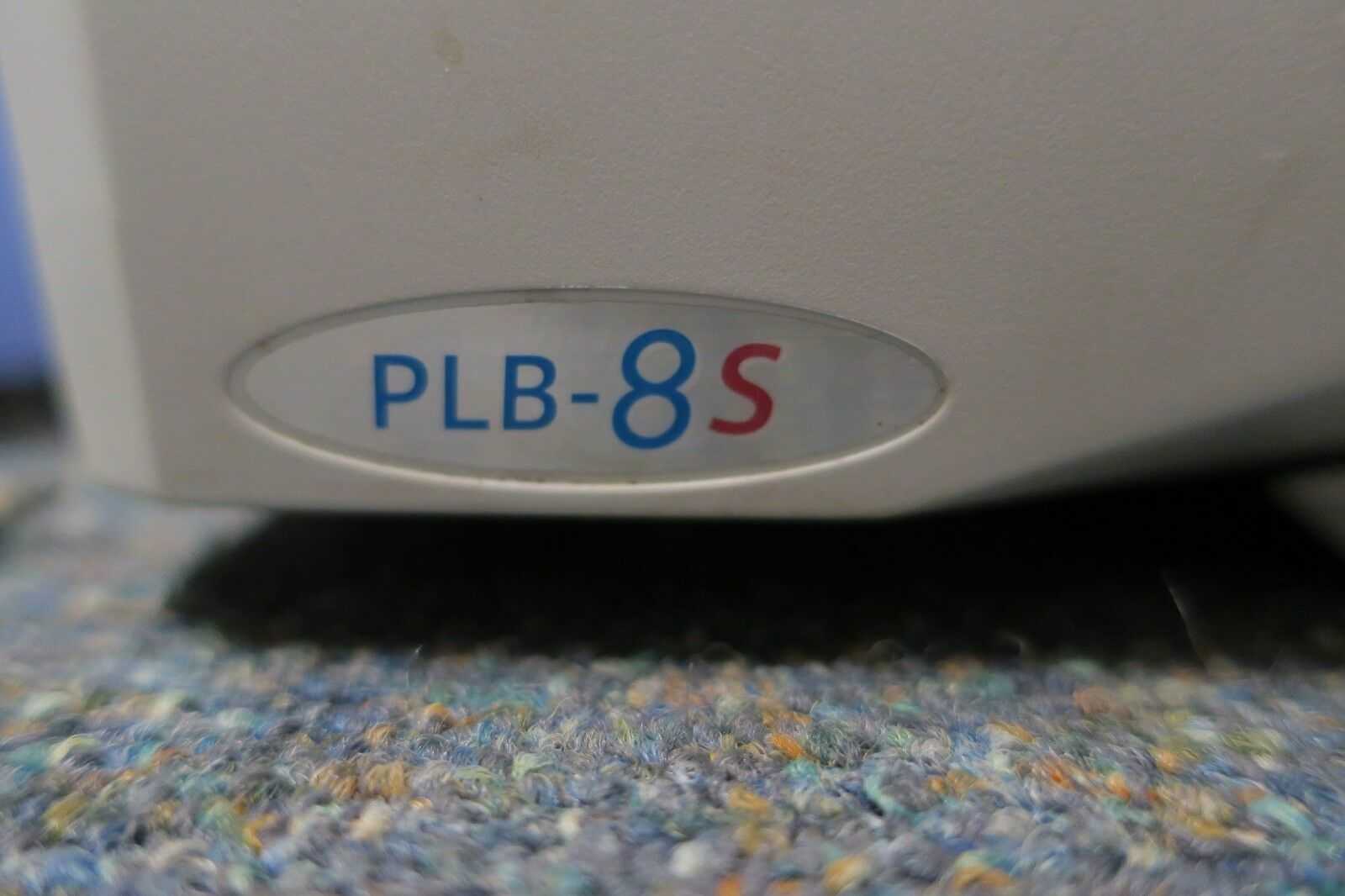

- Step safety bevel / Partial step edging (for type PLB-8S, PLB-2R8S)

- High base curve beveling (for type PLB-8S, PLB-2R8S)

- Design mode (advanced shape editor, partial grooving and beveling, design cut and facet)

Edging Process The Me 1200 / 900 has the most advanced auto-control processing system with an exceptionally rigid, vibration-free direct linear drive lens carriage. With a built-in ability to measure lens volume, it provides the most suitable condition for lens processing, while calculating lens grinding torque.

Automatic 3-D Drilling

The Nidek Me 1200 Lens Edger provides a highly durable rigid design and whisper-quiet operation. 3-D drilling function enables the operator to create various hole shapes such as slots, notches, countersunk holes, and jewel holes. The hole data input can be easily set with a stylus pen on the touch screen which indicates the actual hole size. The hole shape selection is made by simply choosing one of the illustrated icons. In addition, the maintenance interval for drill bit replacement prompted on the screen.

Automatic 3-D Grooving

Semi-rimless groove jobs are processed with pin-point accuracy resulting in highly-attractive lens periphery regardless of lens shape, curve, and thickness. Even when processing high-base curve lenses, the width and the profile of the groove are consistent.

Safety Beveling

Nidek ME 1200 has an ability to safety bevel. Additionally, special safety beveling for the Me 1200 makes the edge of a high minus lens look thinner than it actually is. It can be polished for a high luster.

Step Bevel / Partial Step Edging (Me 1200*1)

With step bevel processing, Rx lenses can be easily mounted into sunglass frames which are traditionally difficult to mount due to uneven eyewire profile. Maximum lens size: ø67 mm (type PLB-8S), ø72 mm (type PLB-2R8S) *1 Type for PLB-8S and PLB-2R8S

Hi-base Curve Lens Processing*2 NIDEK’s unique front and rear independent grinding function offer a high-curve bevel with flawless results. The position and height of the bevel can also be manually controlled. *2 Not available for the Me 1200 type PLB-G

Electronic Estimate System (EES

A newly designed Electronic Estimate System (EES) is incorporated into the Me 1200 / 900. This system provides information on lens measurement, estimation of lens processing time, and automatically controls the selection of lens processing methods. With the EES mode, the processing time is reduced compared to previous models. With EES mode, super hydrophobic coated lenses can be edged without axis shifts.

Processable Lens Materials

The Me 1200 / 900 can process various kinds of lens materials. It is even equipped with the processing mode for the polyurethane lens, used as a polarized lens for sunglasses.

Design Function

The Nidek Me 1200 has all of the state-of-the-art design functions that were incorporated in the previous model. Yet ease-of-use and display contrast are superior with the Me 1200’s newly designed LCD touch screen.

Design Cut (Me 1200)

The Design Cut enables to create a unique lens shape utilizing the drill bit as a milling tool. This allows the operator to creatively design a lens edge or hole resulting in the most intricate shapes, which grinding wheels cannot process.

Facet (Me 1200)

The Me 1200 creates a highly fashionable facet finish on a lens edge, instantly upgrading the value of the eyewear. The operator only needs to specify the facet position and its width on the touch screen. Front and real facets are possible and the finished design can be viewed on the screen in advance.

Partial Step Edging (Me 1200*3)

The partial step is to grind an Rx lens for recent sports frames. Call the shape data of the demo lens from Ice 900 into the Me 1200 and check the layout on its screen. After setting the lens into the Me 1200, processing will be completed by simply pushing its start button. *3 Type for PLB-8S, and PLB-2R8S

Advanced Shape Editor

Customized shapes are easily created with the advanced shape editor. A special “fixed area” function allows the operator to change a particular portion of the lens while maintaining other peripheral areas unchanged.

Partial Grooving / Beveling (Me 1200)

Multiple grinding conditions can be applied to a lens, such as partial grooving, changing the groove width and depth depending on the location. Partial bevel is also available.

Easy Operation

User-friendly

LCD Touch Screen An 8.4-inch color touch screen displays a shape and layout in full scale. Condition settings are easy to understand with intuitive display design. With a user-friendly LCD touch screen, the Me 1200 / 900 allows operators to achieve accurate, reliable and flexible performance with a more simple and easy operation.

Jog Dial

In addition to the intuitive operation of the touch screen, data can also be entered by using jog dials. Pressing the center button moves the cursor to select an item on the screen. Turning the jog dial selects an item or changes an item or value.

Processing Time Indicator

The Me 1200 / 900 measures the volume of a lens, calculating and indicating the anticipated lens processing time on the screen. Additionally, the status bar on the screen shows the processing progress.

Information Bar

Even first-time users can easily operate the Me 1200 / 900 with the assistance of the Information Bar displayed at the top of the screen, which provides helpful “next step” information.

3-D Simulation

Sophisticated 3-D bevel simulation allows checking the bevel placement as if viewing the actual lens for any selected angle.

Voice Indicator (Me 1200)

An audio prompt announces progress time in the process, as well as the end of the cycle, with a corresponding message such as “The right lens will soon be completed”

Auto Edging Door (Me 1200)

With the auto edging door for the Me 1200, the user’s efficiency is further improved.

Design Data Indicator (Me 1200)

The existence of design data is shown on the screen for an easier understanding of JOB data.

Ease of Use

Compact Design

The size of the Me 1200 is 30% smaller than its predecessor. The depth of the unit is minimized so that the back of the device can be moved close to the wall. Maximizing space and the new ergonomic design lends to its ease of use.

Color-coded Pliable Lens Cup

Pliable lens cup are gentle to lens coatings and eliminates axis shifts. These cups are color-coded to process the right and left lens faster and eliminating incorrect lens processing.

Nano Cup

By using Nano Cup, an optional accessory, minimum lens “b” dimension of 15.5 mm can be processed. Specially designed for superhydrophobic lenses, the unit is equipped with an exclusive Nano Cup Mode.

Data Management

JOB data can be backed-up in the USB Memory and transferred to other instruments*.

Ventilation

The Me 1200 / 900 is equipped with a vent hose that can easily connect the lens edger to NIDEK’s deodorizing unit, the LED-200 for aspiration of high-index odor.

Accessory Compartment

Standard accessories can be conveniently stored in the unit’s built-in accessory compartment.

Lens Material

- CR-39

- High index plastic

- Polycarbonate,

- Acrylic resin

- Trivex

- Polyurethane lenses

Polishing

- Beveling

- Flat edging

- Safety beveling

Type PLB-8S

- Finishing wheel for plastic lenses – 100 mm in diameter, 16 mm in width

- Polishing wheel 100 mm in diameter -15 mm in width

- Finishing wheel for high base curve lenses – 100 mm in diameter, 17 mm in width

- Roughing wheel for plastic lenses – 100 mm in diameter, 21 mm in width, 69 mm in total

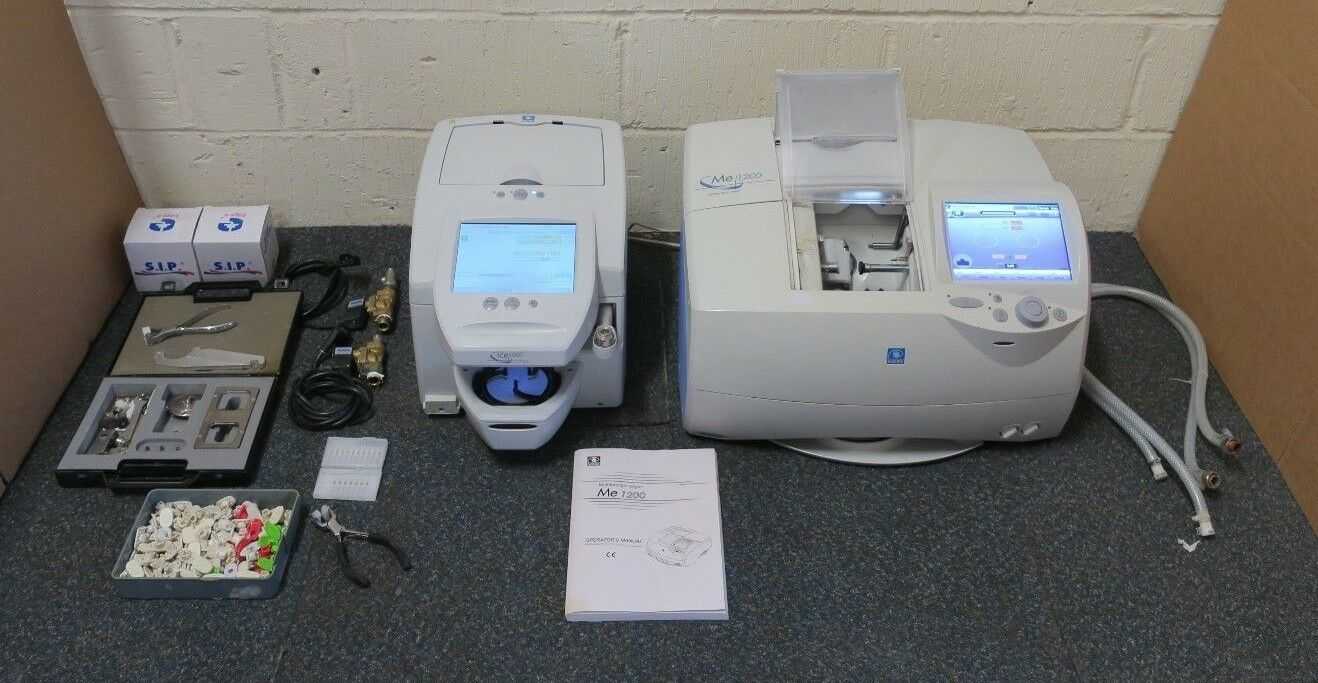

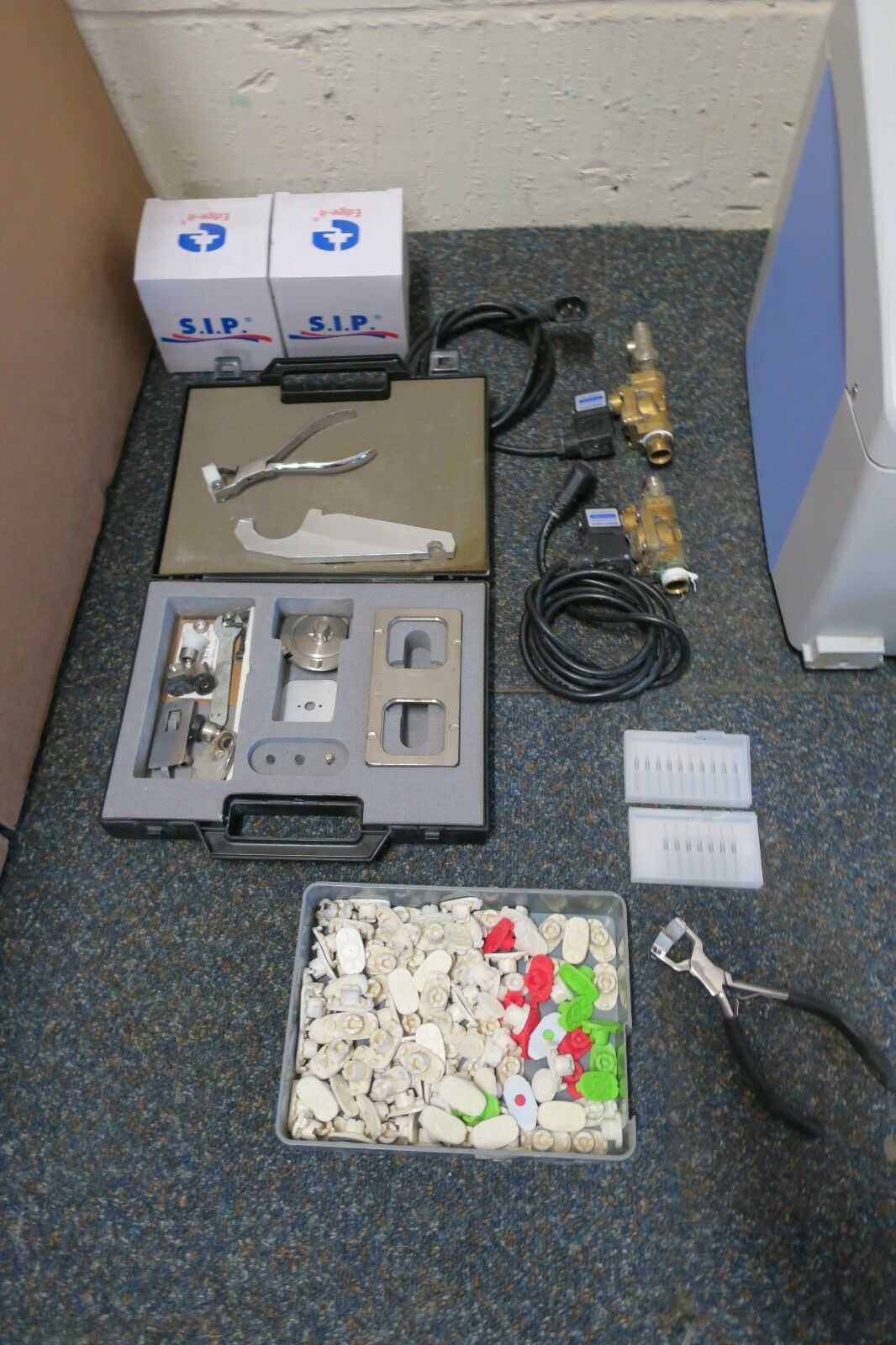

Includes:

- 1 x Nidek 3D Drilling Grooving Multifunction Edger ME-1200 PLB-8S

- 1 x Nidek ICE 1000 Autoblocker

- 1 x Nidek ME-1200 Manual

- 2 x Water Valves & Pipes

- 1 x Selection of Lens drills, Blocks, SIP 4018 stickers and pliers